Shortwave Infrared (SWIR) technology has emerged as a powerful imaging tool, offering unique capabilities that complement Longwave Infrared (LWIR) and Midwave Infrared (MWIR) systems. Unlike LWIR or MWIR detectors, which detect emitted thermal radiation, SWIR detectors primarily capture reflected light, making their imaging properties comparable to visible cameras or the human eye but in the invisible part of the spectrum.

In this article, we delve into the world of SWIR technology, focusing on the recent breakthroughs enabled by InGaAs material, which has facilitated the development of not-cryogenically cooled SWIR imagers. Other materials sensitive in SWIR band have emerged these last years.

In our article on Free-Space Optical (FSO) communication, find out how the Cheetah+ series and our innovative SWIR technology can enhance these systems and help shape the future of global connectivity.

Discover What is infrared radiation

Know more about infrared technology

Understanding SWIR Detectors

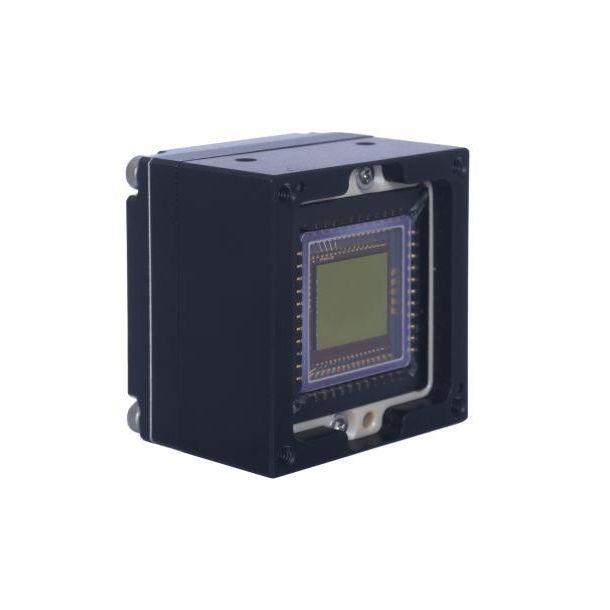

SWIR detectors, like cooled LWIR or MWIR detectors, are photodetectors. However, they differ significantly in their operational principle. While LWIR and MWIR detectors detect emitted thermal radiation, SWIR detectors excel at capturing and interpreting reflected light in the shortwave infrared spectrum. The subset of the SWIR band covered by InGaAs based sensors and imagers typically spans from 900 to 1700 nm, making it ideal for various applications.

Read more about Infrared Detector Types and History of Infrared Detectors

Comparing SWIR and Visible Imaging

One fascinating aspect of SWIR technology is its similarity to visible imaging. Just as visible cameras and the human eye observe the world using reflected light, SWIR images resemble black and white visible images. This unique characteristic bridges the gap between the invisible infrared world and the familiar visible spectrum, allowing users to interpret SWIR images with ease. SWIR's impressive resolution and detail make it valuable in a wide range of industries and applications.

The InGaAs Breakthrough

Recent advancements in SWIR technology have been driven by the development of Indium Gallium Arsenide (InGaAs) material. This cutting-edge material has revolutionized not-cryogenically cooled SWIR imagers, significantly improving their performance and affordability. InGaAs SWIR detectors, in particular, demonstrate exceptional sensitivity in the SWIR band from 900 to 1700 nm, capturing critical information within this range.

Peltier Cooling in InGaAs SWIR Detectors

To maintain optimal operating temperatures, InGaAs SWIR detectors often incorporate Peltier coolers. This cooling mechanism ensures high-quality imaging without the need for cryogenic cooling, making SWIR technology more practical and cost-effective for various applications. Peltier cooling has played a pivotal role in expanding the accessibility of SWIR technology across different industries.

Applications of InGaAs SWIR Detectors

The applications of InGaAs SWIR detectors span across various sectors, offering a myriad of possibilities for industries and researchers. Some key areas where these detectors find extensive use include the following. The benefits provided by SWIR technology in these application segments translate into clear enhancements on today’s concerns: production lines throughput and yield increase, Green-House effect gases emission reduction, energy saving, food quality and safety, waste recycling and reuse and many more.

Industrial Inspection:

The largest InGaAs SWIR detectors application domain. These sensors are instrumental in industrial quality control and inspection processes. They can identify defects, contaminants, differences or inconsistencies in materials and products that may not be visible to the naked eye or traditional visible cameras. More materials used in today’s goods, although very similar in visible light, have very different signatures in SWIR, thus easy to discriminate or see through in that spectral band. For example, Silicon is transparent above 1250nm wavelength enabling see-through inspection in Photovoltaic or semiconductor manufacturing industries for crack or other defect detection or alignment. Similarly, plastics, organic material, metals or minerals have very different response in SWIR although very lookalike in visible light making SWIR imagers particularly effective in food sorting and waste recycling. In addition, most material radiate and emit photons at high temperature in the SWIR band. In steel and glass industries a great benefit can be achieved using SWIR solutions for hot process quality monitoring.

Agriculture:

SWIR technology has proven invaluable in agriculture and crop monitoring. By assessing plant health and detecting diseases in vegetation, farmers can optimize crop yield and reduce the use of harmful pesticides.

Surveillance and Security:

InGaAs SWIR detectors enhance surveillance and security systems by providing clear images even in low light or challenging environmental conditions.

Art and Cultural Heritage:

SWIR imaging aids in the preservation and restoration of artwork and cultural artifacts. It can uncover hidden details, pigments, and features that may not be apparent with visible light imaging.

Medical Imaging:

In the medical field, SWIR technology assists in non-invasive imaging techniques, such as fluorescence imaging, Optical Coherence Tomography (OCT) and vein visualization, enabling better diagnostics and treatment planning.

VisNIR Cameras: Expanding the Spectral Range

In addition to InGaAs SWIR cameras, there are VisNIR (Visible to Near-Infrared) cameras that offer sensitivity in a broader wavelength range, spanning from 400 to 1700 nm. VisNIR cameras provide valuable information in both visible and near-infrared regions, making them versatile tools in various scientific and industrial applications.