Regular inspections of trains and vehicles are crucial to ensure safe and efficient operation. One of the key technologies used in inspection is infrared (IR) imaging. IR imaging allows for non-destructive testing that can detect potential issues that are invisible to the naked eye. This technology can be used in various stages of the inspection process, from identifying hot spots in the engine compartment to detecting leaks in the cooling system or inspecting rolling stocks' temperature.

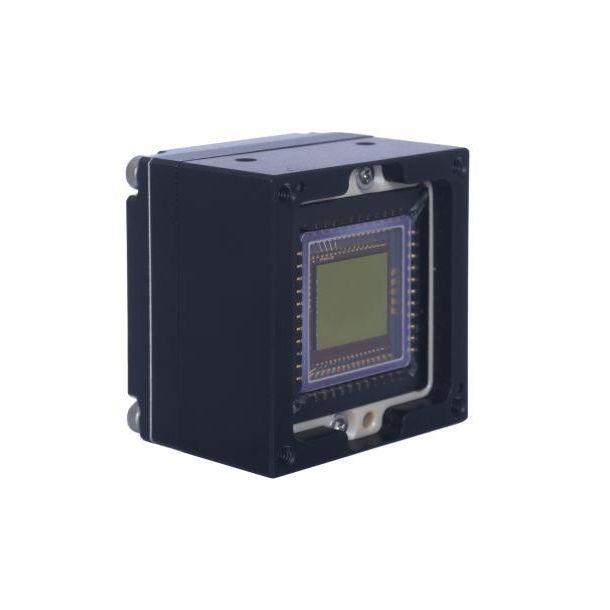

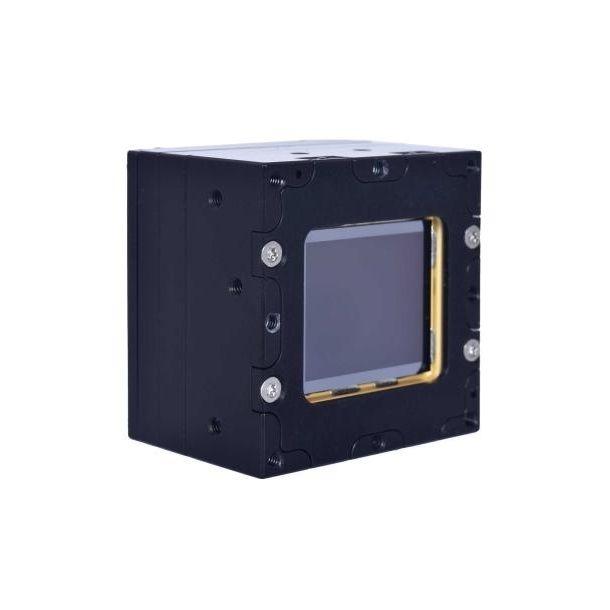

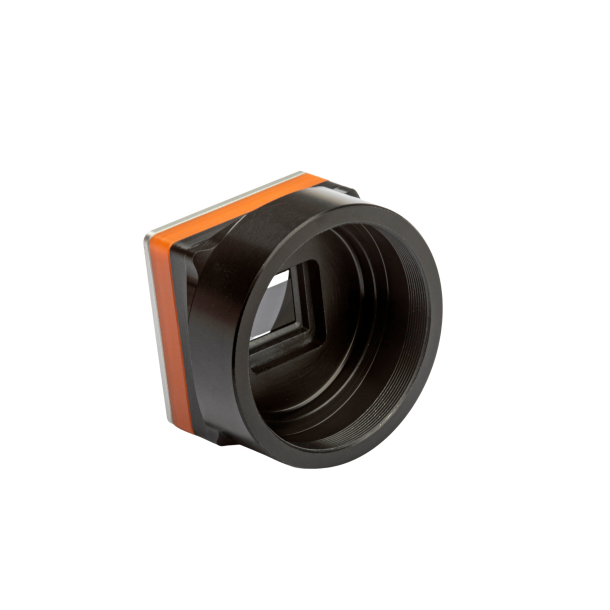

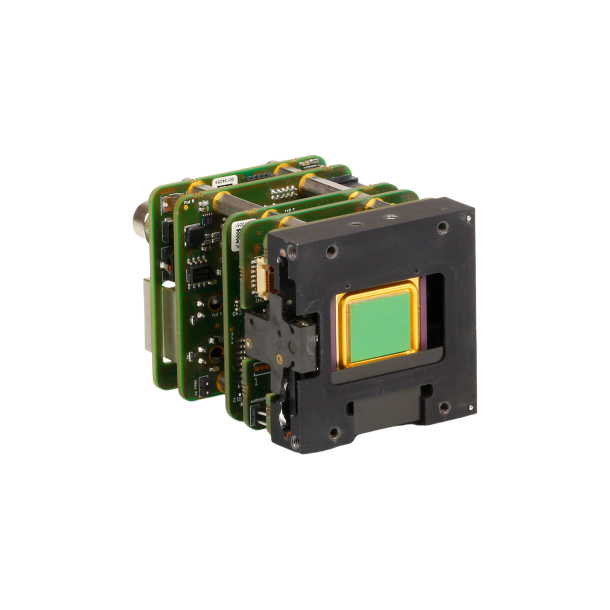

One of the main advantages of using infrared (IR) imaging in train and vehicle inspections is its ability to detect problems early on. Xenics infrared (IR) imaging technology, part of Exosens, can identify potential issues before they become major problems, allowing for repairs to be made quickly and efficiently. This can prevent breakdowns, reduce downtime, and ultimately save costs. In addition, Xenics IR imaging technology can be used to identify safety hazards that may not be visible to the human eye. For example, Xenics IR imaging technology can detect overheating in brake systems, which can lead to brake failure and potentially dangerous situations. By identifying these issues early on, safety risks can be reduced and prevented.

Another advantage of Xenics infrared (IR) imaging technology is its ability to improve the accuracy of inspections. Traditional inspection methods may rely on visual inspection alone, which can be limited in detecting certain issues. With Xenics infrared (IR) imaging technology, inspectors can identify issues that may be hidden from view, such as internal engine components or undercarriage areas. This results in more thorough and accurate inspections, reducing the risk of potential problems and ensuring safety compliance. Overall, the use of Xenics infrared (IR) imaging technology in train and vehicle inspections applications offers numerous benefits, from early detection of potential issues to improved safety and accuracy. By leveraging our technology, transportation companies can enhance their inspection processes and improve the safety and efficiency of their operations.

Need some answers? Ask our experts!

Contact usProducts 11

See all exosens products