Thermal processes are integral to numerous industries in material engineering, encompassing operations such as melting, forming, and drying. Due to the high temperatures involved, it is crucial to monitor the cooling phase after heating to ensure safe progression to subsequent steps or storage. Excessive heat can complicate later production stages and, during storage, may pose fire risks that could disrupt operations, damage products, and compromise facility safety.

The long-wave infrared (LWIR) wavelength range is well-suited for temperature detection. LWIR cameras operate in the 8–14 μm spectral band, ideal for capturing emissions from objects at temperatures up to 400°C. These cameras require no external lighting and are unaffected by natural light conditions. Equipped with microbolometer arrays, each pixel acts as a tiny thermometer, enabling the generation of high-resolution thermal maps of the observed area. When properly calibrated, these devices can measure absolute temperatures, making them a powerful tool for thermography and real-time temperature monitoring.

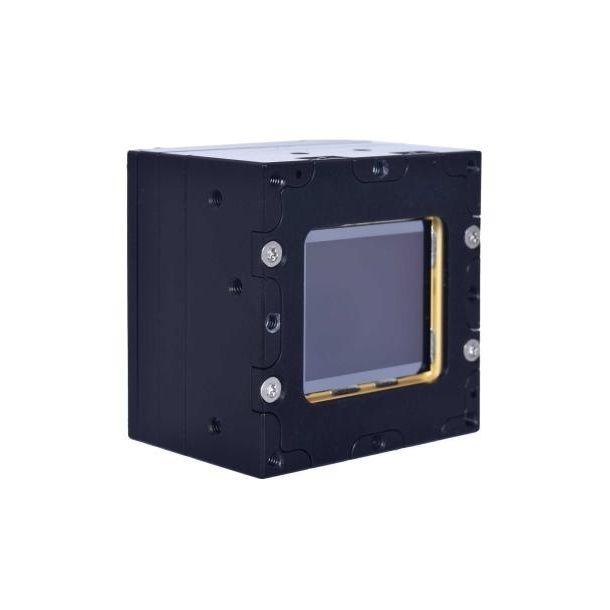

Exosens brings extensive expertise in developing uncooled thermal cameras designed for thermographic applications. Our solutions (Ceres series, Crius series, Dione series, MicroCube series, Gobi+ series and many more) featuring diverse interfaces and resolutions, integrate effortlessly into industrial systems. With temperature calibration capabilities, our LWIR cameras deliver highly reliable system for measuring absolute temperatures.

Need some answers? Ask our experts!

Contact usProducts 6

See all exosens products