Global electricity demand is on a steady rise. To guarantee safe and reliable delivery, we need resilient power grids with enhanced energy distribution capabilities. Aging infrastructure presents vulnerabilities and outage risks. Exosens offers cutting-edge imaging solutions designed specifically for critical power grid and line surveillance. Our solutions empower proactive wildfire prevention, optimized preventive maintenance, and significant maintenance cost reductions.

Need some answers? Ask our experts!

Contact usCorona Discharge Detection In Power Lines

What is Corona Discharge ?

The phenomenon of electrical discharge in high voltage transmission lines and substations. It occurs when the surrounding air around the high voltage conductors is highly charged and ionized. It can happen for voltages as low as 300 V. Hissing noise and violet glow are typically observed with corona discharge.

Learn more about the corona discharge :

Impacts of Corona Discharge

Corona discharge leads to damage in insulation systems present in high voltage applications. For example in power grid lines, defaults in high-voltage short circuit and its interaction with surrounding air, causes electromagnetic radiation to be emitted in the UV region of the spectrum. It then results in loss of energy and damage of insulation systems. The other effects of corona discharge are production of high frequency noise in the power lines that interferes with the nearby radio receivers and TV sets and the production of ozone gas that reduce the life of insulators and conductors.

For energy operators, the occurrence of corona discharge and its associated effects will cause several setbacks:

- Companies are affected economically due to energy losses as a result of poorly maintained electrical networks and corona discharge.

- Accelerated degradation in lines and insulators due to corona discharge.

- Accidents occurring due to corona discharge and sparks especially when the lines are near to forest areas and eventually resulting in wildfires.

- Additional time and efforts to implement corrective actions to reduce the discharges and avoid further power losses.

Hence, it is important to detect corona discharge at the earliest stage as part of a maintenance regime to ensure the power lines work efficiently.

Solar Blind UV Detection for Corona Discharge in Power Lines

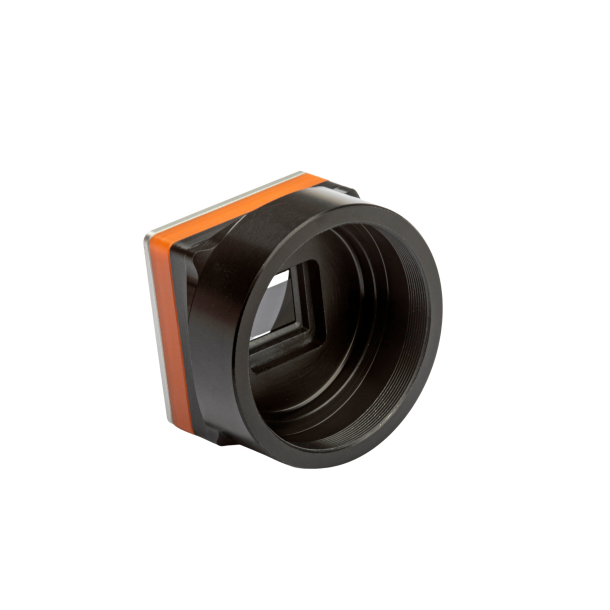

Solar blind UV also known as SUV is an accurate and reliable detection solution to locate and image the partial discharge even during daytime. With detection spectral band from 240 nm to 280 nm, it filters out the sun radiation and allows for UVc detection during daytime. SUV cameras can also be used at safe distances or mounted on aerial platforms (like drones, helicopters etc). This type of detection is performed using a camera based on the coupling of an Image Intensifier Tube (IIT) optimized on the SUV waveband and a CMOS camera to ensure a good sensitivity in the SUV spectrum. SUV allows for an early detection even before hot spots/heating and damaging flash-overs are observed.

Photonis, a Leading Brand of Exosens Offers Advanced Imaging Solutions to Detect Corona Discharge in Power Lines

Photonis, a leading brand of Exosens offers advanced imaging solutions to detect corona discharge in high voltage power lines with SUV solutions. Photonis SUV (iNocturn SUV) solutions are based on the coupling of image intensifier and a CMOS high performance detector for high precision corona discharge detection.

Power Line Defect Detection Due to Rising Temperatures

Global warming is pushing temperatures higher, creating a double threat for the power industry: increased demand during scorching summers and heightened strain on equipment due to continuous heat. Traditionally, summer meant a surge in power system failures. Now, with rising temperatures, power facilities face extended periods of stress throughout the day. Overheating of insulators and the growing risk of wildfires add to the challenges. The answer lies in more frequent inspections and maintenance procedures to ensure safe and reliable electricity flow. Long-wave infrared (LWIR) cameras emerge as a valuable tool in these efforts, helping detect faults early on to prevent hazards and maintain a normal power supply.

Traditional power grid maintenance means service disruptions, risky contact, and lengthy disassemblies. LWIR cameras, powerful tools that see the invisible, revolutionize this. They inspect live equipment, eliminating risks and streamlining the process. These cameras pinpoint degradation, identify fault locations, and diagnose issues before they become problems. Imagine detecting uneven heat in an insulator before an outage – LWIR cameras make this possible. They excel at real-time monitoring of transmission lines, detecting temperature spikes that could trigger wildfires. This proactive approach safeguards your grid and the surrounding environment.

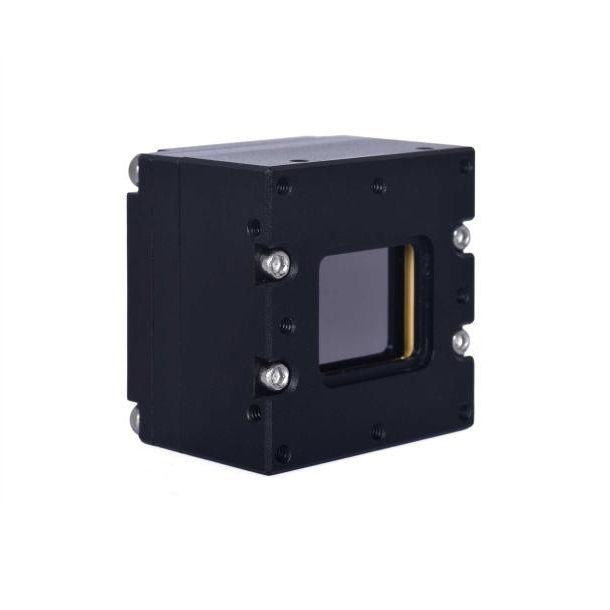

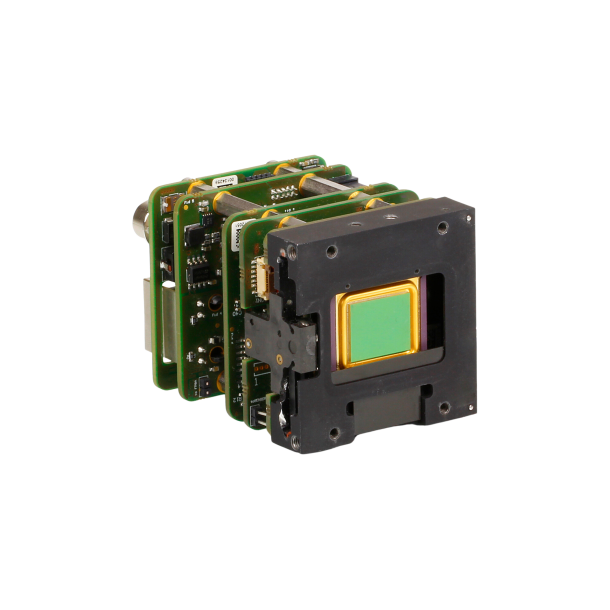

Xenics, a Leading Brand of Exosens Offers Advanced Imaging Solutions to Detect Power Line Defects Due to Rising Temperatures

Xenics, another leading brand of Exosens offers advanced imaging solutions to detect power line defects with LWIR solutions. Xenics LWIR cameras and cores consists of SWaP features and are available in industry standard interfaces of MIPI CSI-2, USB and UVC for power line defect detection.

Products 12

See all exosens products